Wine growing has become very popular. Summer residents and gardeners, in vain, plant more and more new varieties, and therefore they are faced with the question of what to do with the crop surplus. As a rule, they are allowed to juice or wine. For the production of drinks and a press for the grapes is needed, which can not only be bought, but also made by hand. There is nothing difficult here, you just need to have on hand some drawings, materials and tools.

Table of contents

What is a grape press?

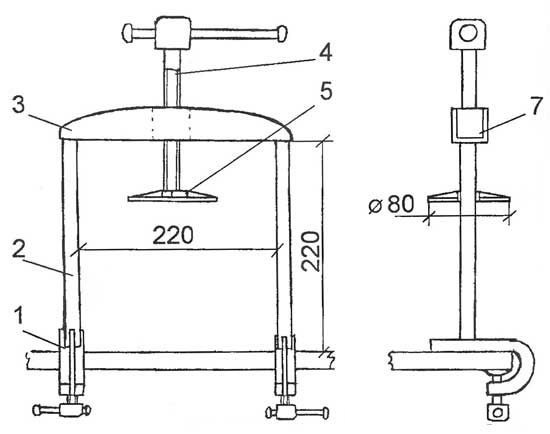

Press for grapes is considered to be a juicer, characterized by certain features of the design. Its basis consists of:

- frame;

- juice collection tray;

- barrel;

- pressing element;

- filter mesh;

- power screw.

The principle of operation is based on a simple procedure: the grapes are loaded into a basket, and then the juice is squeezed out of it using a screw mechanism.

Stainless steel is an excellent material for making grape presses. Due to the minor contact of the elements, the parts do not heat up, which is important. This equipment allows you to carefully squeeze the juice from the berries and increase the yield of the finished product.

Home Use Policy

After the assembly, the finished press should be installed on a smooth and even surface and try to fix as much as possible. Manual apparatus, as a rule, is installed on top of a container for collecting pulp. Excellent plastic or stainless tanks, barrels.After that, in the ladle impose prepared berries, which will be poured out directly on the rolls. Pre-laid on the bottom of the basket napkin to collect the cake.

As the press rotates, the grapes will be crushed and turned into mashed potatoes, from which the juice is obtained. Before loading in the bucket berries must be removed from the brushes.

Varieties of Grape Press

There are several key features according to which presses for grapes are divided into species. First of all they can be:

- mechanical;

- electrical;

- universal.

The first are characterized by an affordable price, but at the same time good performance and compact dimensions. With small volumes, this is almost an ideal option for a home winemaker. However, the work requires great physical effort.

The basis of the second type of work are pneumatic and hydraulic presses.The design of the device itself in no way impairs the taste of the original product. The pumps that make up this equipment are powered by electricity. The performance of such equipment is very high, and the physical effort required is much less.

- On the universal press you can push any vegetables and fruits.

- Mechanical press

- Electric press for industrial use

Such devices are very popular. Factory products of this type are produced in various capacities and are designed for a variety of production volumes (from home winemaking to industrial).

According to the materials of which the crush presses are made, they can be classified into:

- wooden;

- metal.

Products made of wood are considered the most environmentally friendly. However, they require careful maintenance and disinfection. Metal presses are predominantly made from cast iron or stainless steel.They are more hygienic and durable compared to wooden counterparts.

- Wooden press view

- Metal press

How to make a homemade press for grapes do it yourself

In the manufacture of homemade hydraulic press at home for the grapes there is nothing difficult. From scrap materials you can make a simple device that will significantly facilitate the life of the winemaker.

- It is necessary to prepare a container for loading berries of the required size. To this end, a drum from an old and broken washing machine may fit. Holes are made in the walls of this tank with a drill, placing them in a checkerboard pattern.

- Find a container that will be at least a little more than the previous one. At the same time it should be without a bottom, and additional holes should be made below.

- Prepared vessels insert each other, and between them to establish a bar of wood, thus creating the necessary clearance.

- From the tree you need to make a frame having the shape of the letter P. On its crossbar install a thick pancake made of cast iron or stainless steel. To fix it, you need to make an additional hole in the frame.

- Place both containers in a large basin. It can be made from any polymers intended for working with food products. In the pelvis pre-make a hole for the hose, through which the juice will flow.

- U-shaped frame concreted in the ground. It will serve as the basis for the working mechanism. Mount the previously assembled structure of the pelvis and two containers onto it.

- Prepare a container for collecting juice in which to lower the second end of the hose.

- Load grapes into the drum and cover it with a shield made of stainless steel or wood. On top of the shield to lower the pancake. Push control with a lever.

- Allocated juice will gradually flow through the diverted hose.

After the first spinning, high-quality juice is obtained, which can be used not only for making wine, but also to be consumed fresh. The second and subsequent spinning give less quality product from which to produce alcoholic beverages. You can also mix the juices of different spins, which will significantly improve the characteristics of the final product.

As you can see, a simple press for grapes is quite possible to make their own hands. There is nothing difficult in this procedure, but the product will serve as a good helper in home winemaking. The cost of materials will be small and quite justified.