Pine nut is very popular among lovers of this healing product. Cones with kernels can be collected in the forests of Siberia, but further processing of nuts is quite complicated. Previously, the kernels were manually separated from the bumps, but this process is very laborious and also takes a lot of time. Now, With the advent of new technologies, special cars have appeared., whose activities are aimed at peeling and processing of nuts. Such mills, today, can be made with your own hands, as discussed in this article.

Table of contents

Varieties of devices for peeling cones and cleaning pine nuts

The modern market offers a huge selection of different equipment, thanks to which the cleaning and preparation of pine nuts for use is much easier.

At large enterprises, a whole band of apparatuses is usually used, thanks to which the source material is fully prepared for sale practically without human help. Usually, such tapes consist of special equipment, alternately performing the following functions.:

- so that the process is started correctly pine cones are first dried;

- then kernels are separated from the bumps with the help of cone crushers and winnowers;

- shelled nuts;

- clean edible kernels from various impurities and cones;

- then with pine nuts remove the film;

- again washed, dried and packaged for resale.

At the enterprises you can find the following devices:

- Machines that are engaged by calibrating an already cleaned nut into fractions to size.Such devices handle an average of 160 kilograms of nuts per hour, and their the cost starts from 85 thousand rubles;

- A machine whose work is aimed at pine cone crushing (peeling). Some samples dump all the processed "in a heap" and a person has to manually sort through the cores and debris, while other machines are equipped with a blowing system that separates the nuts from parts of the cones and distributes them into different compartments. The cost of the combined machine on average is 120 thousand rubleswhile it can process up to 200 kilograms of product per hour;

- The next step will be shell removal, for this purpose, special installations have been created, which with the help of various mechanisms exfoliate the shells from the nuts. Average performance equals 70 kilograms per hour, and the price 100 thousand rubles;

- Also very useful will be the machine that separates the film from the nut, while almost without hurting the finished product. This device is capable of carrying through itself up to 500 grams of nuclei per hour, but also its price will also be quite high, no less 150 thousand rubles;

- One more a useful device would be a roaster, which in 30 minutes is able to prepare for consumption up to 40 kilograms of nuts, while there are instances that additionally produce preliminary washing of the product. The price of such a device starts from 130 thousand rubles.

- Cedar Nut Core Film Removal Machine

- Cedar Nut Crushing Machine

- Pine nut shelling machine

- Pine nut roasting machine

- Peeled Pine Calibration Machine

Can I make a pine nut crusher with my own hands?

Of course, the acquisition of special machines is a good thing, but even they have several drawbacks.:

- Such machines very expensive and for this reason, they are not available to small entrepreneurs and just ordinary residents who collect nuts for their needs.

- In addition to the price of a special installation takes a lot of space, and its use will be inconvenient in the presence of a small warehouse.

- Also, many people collecting and storing nuts note that it would be very convenient to first separate the kernels from the cones, and only then transport almost pure nuts. This is due to the fact that in a cedar cone nuts occupy less space than inedible elements. Special equipment is powered by electricity and its delivery to the collection sites is impossible or simply inconvenient, therefore making a more compact means for crushing pine nuts could be an excellent way out.

All the minuses of the special technique best emphasize the advantages of the home-made device.:

- Low cost price;

- Possibility of use as for small business and for personal use;

- Such crushers take up less space and they can be transferred to the gathering place and accordingly not to bring unnecessary parts of the cedar cone from the forest.

Having considered all the advantages and disadvantages, many will say that special equipment is safer and in this they will be right. But why do we need an apparatus that costs more than 100 thousand rubles for a simple resident who harvests several kilograms of nuts for his family. In this case home-made crushers are the best fit, which is quite simple to do with the availability of tools, material and some skills. In principle, everyone can build such a structure; the main thing is to make a little effort. Especially for the manufacture of such a crusher will require a minimum of financial investments.

Homemade pineapple grinder

The made shellaker consists of the bunker and the drum rotating in it with 54 hairpins peelers. Wherein in this design, you can customize the crushing on small and large nutsthat helps to improve the quality of processing. This crusher is driven by a manual rotating mechanism, the principle of operation is similar to the work of a meat grinder.

The main features of this design include the possibility of its attachment to the tree with holes in the back wall. And the main advantage is the low cost of the required parts.

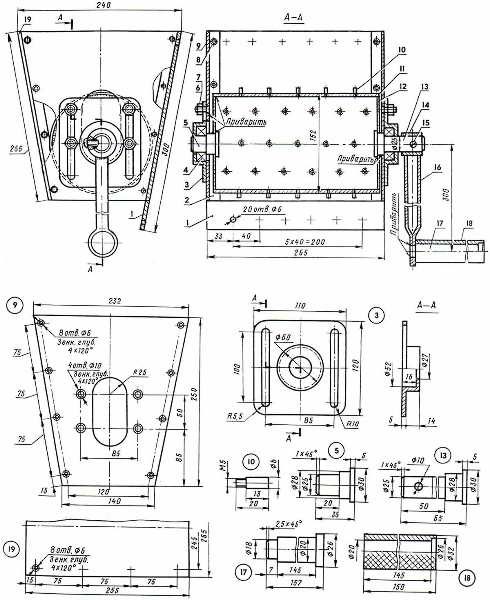

Drawing shredder

Required materials and tools

The list of necessary materials can be considered by deciphering the legend in the drawing.:

- back wall, 4 mm steel number 3;

- stand-edge, steel corner 2,5x2,5 centimeters, 4 pieces;

- bearing housing in 2 copies of steel number 3;

- ball bearing 205, 2 pieces;

- left half of steel number 5;

- bolt M10 with hidden head, 8 pieces;

- nut M10, 8 pieces;

- screw M6 with hidden head, 32 pieces;

- side wall from 4 mm steel number 3 in 2 copies;

- hairpin - peeler, izogotlivatsya from a metal rod with a diameter of 6 millimeters, 54 pieces;

- drum, 25 centimeter length of pipe 152x7, steel, seamless;

- sidewall , 4 mm number 3 steel in 2 copies;

- right half of steel number 5;

- grip sleeve, 3 centimeter length of pipe 32x3.5, steel, seamless;

- pin- screw M10;

- arm grip, 30 centimeter length of pipe 20x3.5, steel, seamless;

- handle shaft of steel number 5;

- fluted handle, 15 centimeter length of pipe 32x6, steel, seamless;

- front wall out of 4 mm steel number 3.

Required tools

- hacksaw;

- electric or gas welding;

- drill;

- Bulgarian;

- screwdriver, screwdriver;

Action algorithm

To make a pine nut grinder by yourself, you need to adhere to the following algorithm.:

- First, from a pipe length of 25 centimeters make drum, screwed to it in staggered studs, peeler, cut from steel bar with a diameter of 6 millimeters;

- The sides in the form of a disk are welded to the drum. and make a hole exactly in the middle;

- Manufacturing bearing units It is best to entrust the professionals, because ideally they should look like whole pieces of complex shape;

- But also bearing units can be made independentlyonly in this case it is better to weld individual parts (from a 5 mm steel plate with the required number of holes, 2 centimeters cutting a steel pipe without a seam size 60x4 and washers 3 millimeters thick, inner diameter 2.7 centimeters and outer diameter 5.4 centimeters;

- On the right half of the axis stick on the handle, which will subsequently trigger the mechanism;

- Sleeve, handle arm and grooved handle made from scraps of pipes of the desired size, and the axis of the steel sheet number 5;

- Then lower end 30 centimeter tube shoulder flatten and sawn, then in the resulting wall make a hole with a diameter of 1.8 cm for the passage and subsequent fixing of the axis of the handle;

- Sleeve, handle arm and axle connect by welding;

- As soon as the drum is ready it framed by walls of 4 mm steelwhich will be assembled into a single design using the corners of 2.5x2.5 centimeters and countersunk M6 screws;

- To fit the drum inside the structure, grooves in the side walls radius of 2.5 centimeters;

- Then need install ball bearings (in accordance with the drawing);

- Next to the grooves bolts are welded to the side walls M10, put on them the housings of bearing units and fix them with nuts.

The most complete understanding of the algorithm of actions is possible only after the drawing has been fully studied.

Making a pine nut crusher is not so difficult with your own hands, the main thing is to follow the drawing and a specific algorithm of actions. With a minimal amount of financial investment, you can get a structure that greatly facilitates the process of processing pine nuts.